Why is mounting equipment important

Mounting equipment is important to position the printing plate on the right place and parallel to a printing cylinder or sleeve.

For every printing machine it is important to get the plates exactly parallel on a sleeve or print cylinder because this can not be adjusted in the printing machine. It is also important to mount the plate with-out air bubbles between plate tape and sleeve or cylinder.

If the plates are not parallel it will affect the quality of the print result and the plate needs to be remounted and the machine will have to wait for this.

For the MPS machine it is also very important to mount the plates in reference to the zero line of the sleeve or print cylinder to reduce the set-up waist.

The auto register system of all MPS machine are using this.

So resuming good quality of mounting can help to:

- Improve register quality

- Improve print quality

- Reduce set-up waist

MPS Dedicated Mounting System

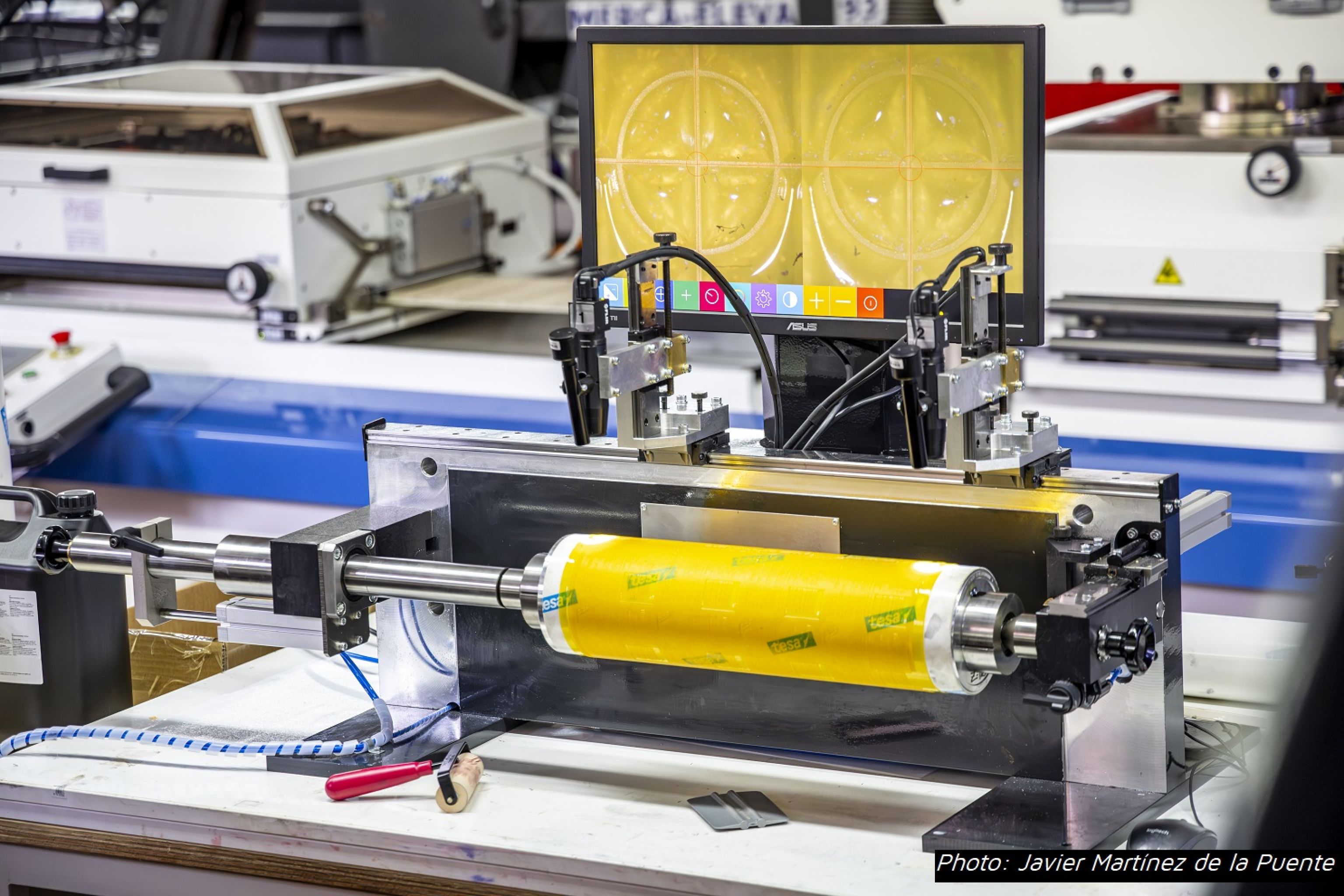

A fixed mandrel, flexographic plate mounting machine for very simple, accurate and quick mounting of flexo plates directly onto sleeves commonly used with today's quick change presses, either geared or gearless.

Units are designed for mounting single plate configurations which are mounted with total accuracy eliminating on press register issues and increasing print quality.

An air mandrel is supported at both ends during the mounting operation ensuring the sleeve is exactly parallel with the cameras and a pneumatically operated support arm pivots away from the end of the mandrel with a quick release exhaust valve to allow for very fast sleeve change-over. The unit can be set up with a single air cylinder diameter or multiple diameters depending on exact press specifications.

- High magnification video cameras (90x or 140x)

- Split screen monitor with microdot and cross references

- Pneumatic circumferential indexing for plate stepping

- Rigid Steel Support Cupboard

- High precision machine components with linear bearings

+++ Advantages:

- Flexible equipment

- Simple to operate & maintain

- Ensures high mounting accuracy

- Requires minimal training

- Economically priced for a low investment cost

- Versatile configuration to accommodate multiple presses on a single mounter

---- Disadvantages:

- The printing plate must have two parallel mounting symbols.

- Accuracy depending on the skills of the operator.

- Plate must be pressed by a roller to get rid of air between plate and tape.

This video is to show how to use MPS dedicated plate mounter.

This video shows the perfect register after plate mounting with MPS dedicated plate mounter

Hear from our customer

The team praised its user-friendly interface, precise graduation, and stable camera position, all of which help streamline the mounting process and improve plate mounting accuracy and speed.

Interest to MPS dedicated plate mounting system?

Drop us an email now to get more information or request a quotation!

Looking for an automated plate mounting system?

MPS has the solution too! Click to know more.