Raising the bar in print

Flexo remains as the leading print technology in the narrow web market for label and segments of packaging printing. Four reasons are:

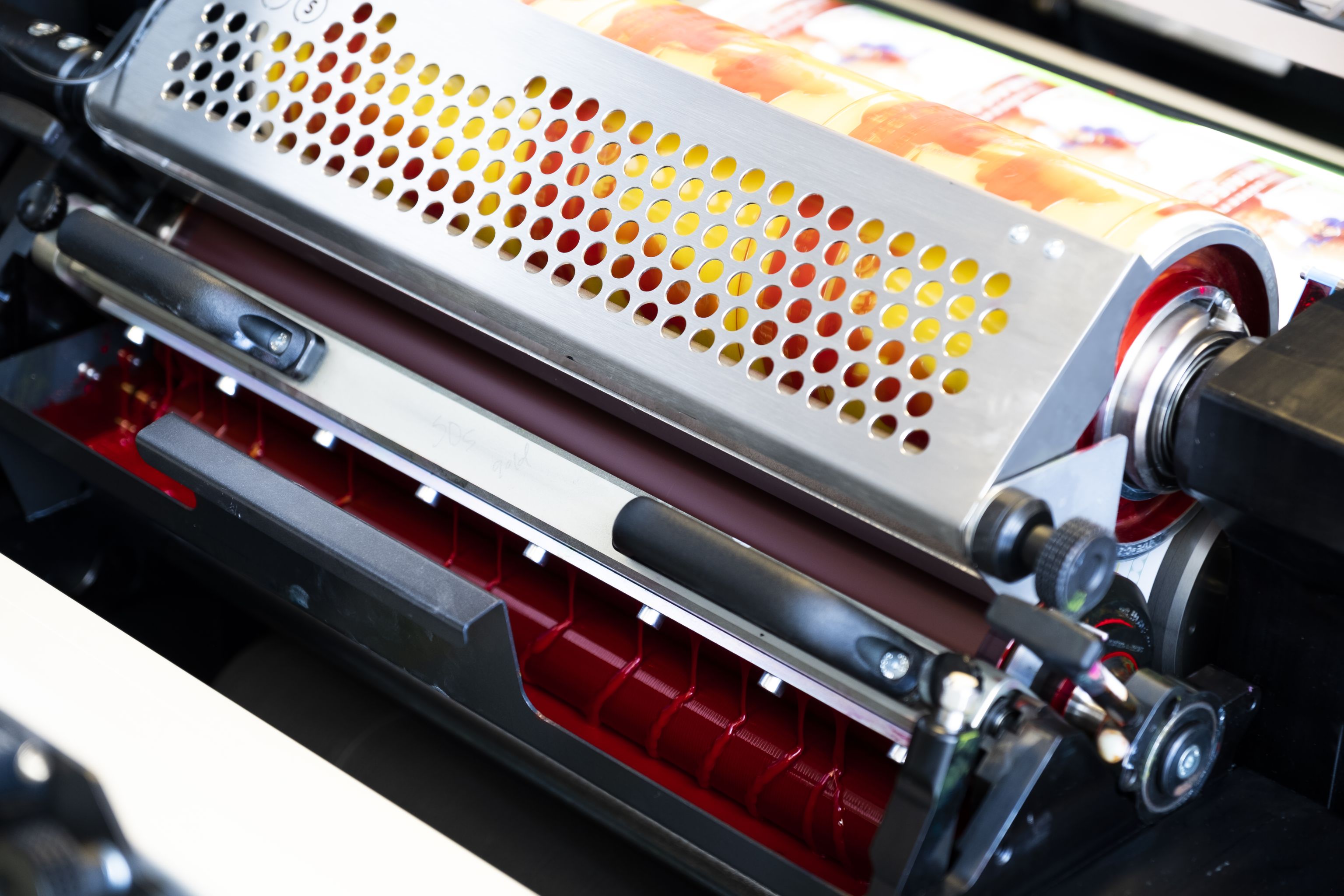

Quality: Flexo quality meets the standards of offset and gravure printing, due to ongoing developments of the printing plates, inks, aniloxes and the accuracy of the press.

Faster changeovers: Thanks to technology like Job Memory and an open ink system, change-over times have reduced dramatically in recent years.

Versatility: Printing on a wide range of substrates is possible with flexo.

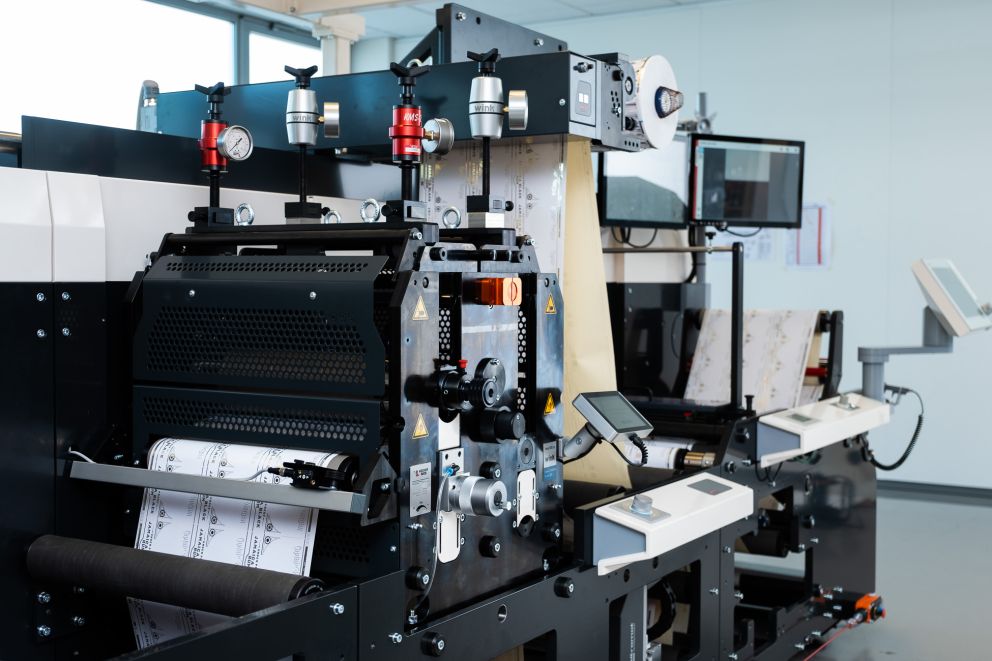

Automation: Print sleeves are loaded automatically on the print unit and desired print pressure settings are automatically set.

Machines suitable for flexo printing

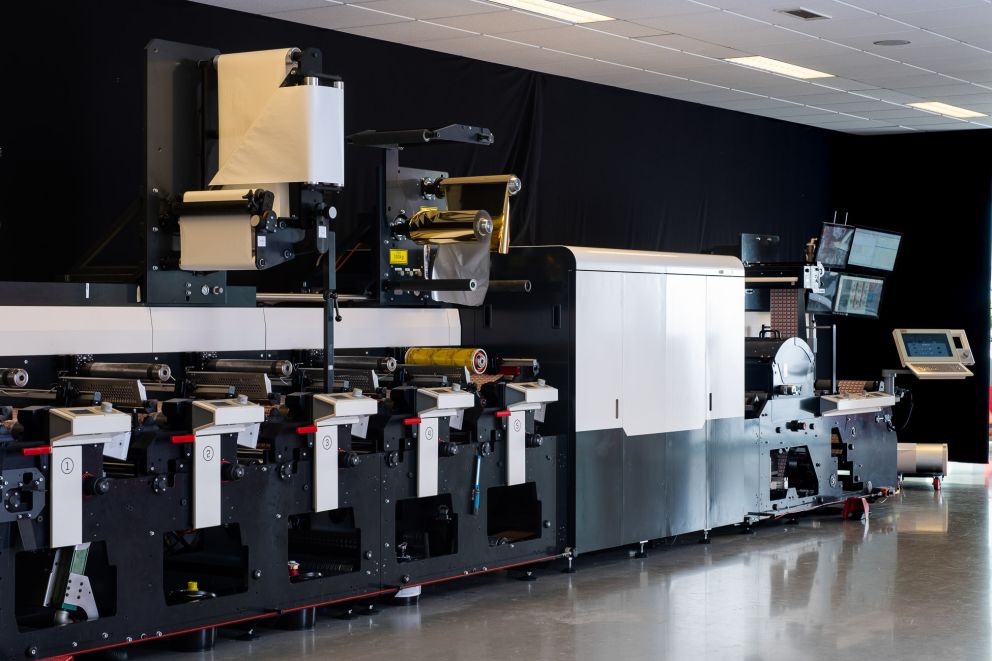

Building on the acclaimed MPS EF narrow

web press series, the EF Packaging Press

extends capabilities to flexible packaging and

shrink sleeve applications with an impressive

26” web width, opening new opportunities

for label converters and flexible packaging

businesses.

the flexible packaging solution

www

Speak with our specialist

Do you have aquestion about one of our presses? Wondering if our machines can accommodate a special application? Looking for more information about our MPSConnect connectivity services and performance improvements? Whatever you need, our team of print experts are here to assist you.